used car sales lafayette

Once shaped, the boxes can be treated with various finishes, including painting, lacquering, and printing. This not only enhances visual appeal but also provides additional protection against moisture and other environmental factors. The final step involves quality control to ensure that each box meets the required specifications and standards, ensuring that clients receive a product that aligns with their expectations.

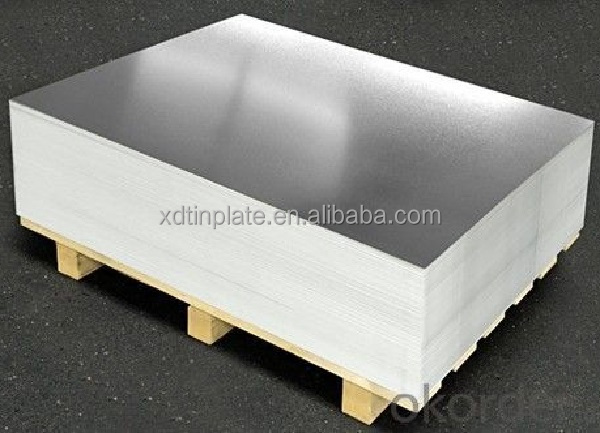

rectangle tin box manufacturer

cast iron or galvanized steel supplier

Furthermore, the manufacturing technology in asphalt sheet roof factories has advanced significantly over the years. Automated systems enable higher precision in measurements and designs, resulting in consistent quality across products. Additionally, these factories often implement rigorous quality control measures to ensure that every sheet produced meets specific standards, thereby reducing waste and enhancing overall sustainability.

asphalt sheet roof factories

2. Corrosion Resistance Many metal flashing products are treated with protective coatings or are made from materials like aluminum or stainless steel, which are naturally resistant to rust and corrosion. This property ensures that the flashing maintains its performance and appearance over time, which is crucial for maintaining roof integrity.

flashing roof metal sheet manufacturer